About our

• International quality standards certified manufacturing factories located in Malaysia and China

• We are an engineering company creating value-added services to multinational and OEM clients

• Dedicated organizational structure, from Sales/Program, Engineering, Material Planning, Production, Supply Chain, Quality Control, Logistic & Warehouses, HR/Admin to Finance department.

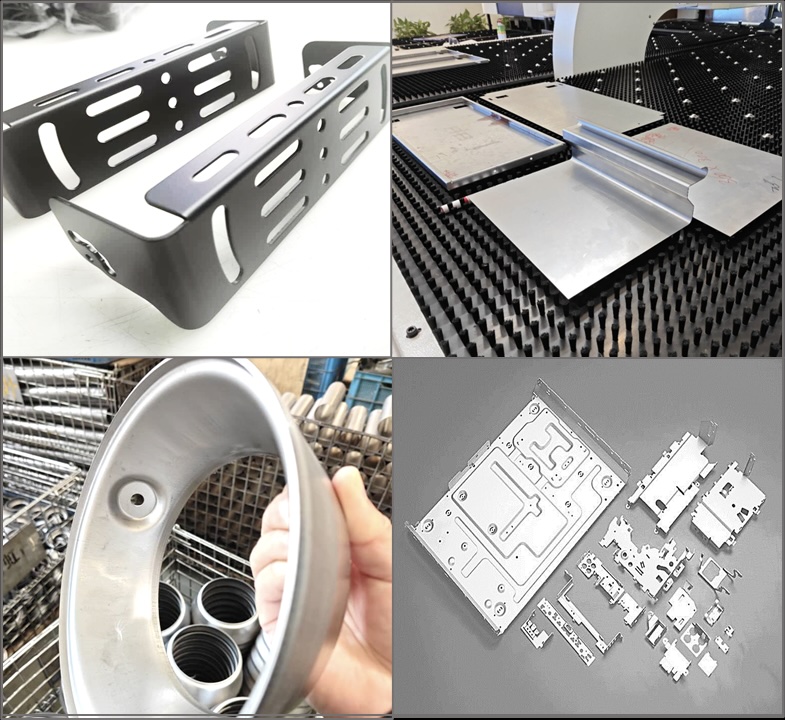

• Combination of different machineries such as high-speed high-tonnage and CNC machines

• Total 55 units of Japanese and branded stamping machines range from 30, 60, 80, 110, 150, 160, 200, 250, 400 and 600 tons, including high speed microstructure stamping machines

• 12 units of CNC laser cutting, turret punching, and bending machines

• We support different lot size production, especially High-Mix/Low-Volume Production.

• Serve wide range of industries and products, such as electronic components, sheet metal covers, equipment panels and fabricated structures.

• Provide necessary surface finishing treatment and secondary processes, such as paint coating, plating, silkscreen printing, hardening, fastener inserting, spot welding, and assembly.

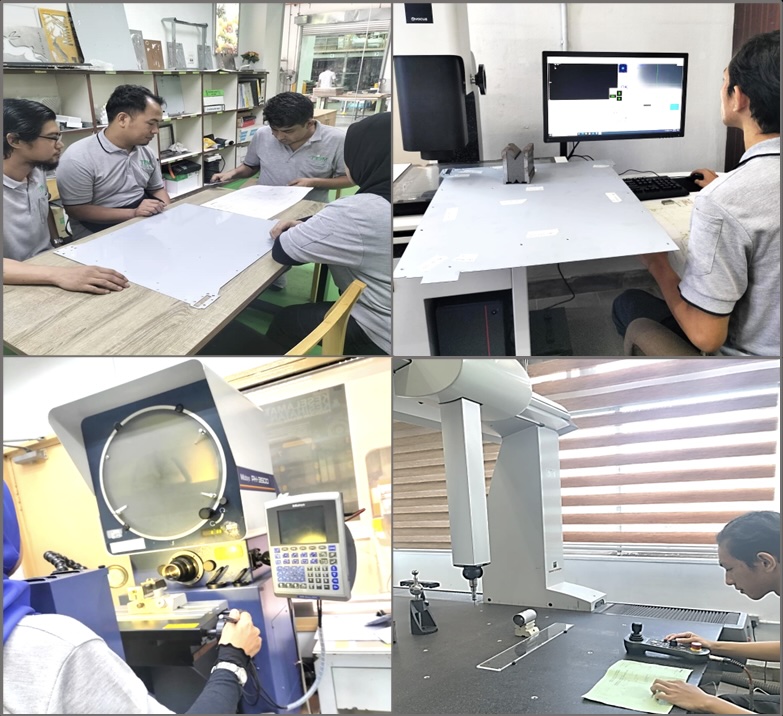

• Quality assurance and digital quality control equipment ensure high quality products for customers.

• Our experienced engineers can understand and meet international clients’ quality standards and requirements.

• Our “Quality 1st Culture” always drive success of company, as well as gaining clients’ recognitions and satisfactions.

• Combination of using inhouse hard tool (stamping) and soft tool (sheet metal) capability benefit our clients in new product development, as well as maximize product development cost.

• We help customers in hard tool (stamping) and soft tool (bending) design and manufacturing.

• MIG, TIG, Laser Welding and Spot Welding

• OEM equipment building

• Industrial and machine structure fabrication

• Powder/paint coating, sand blasting

• Machine assembly, Field Application Testing (FAT)

• On-site machine installation and commissioning

• International quality standards certified manufacturing factories located in Malaysia and China

• We always create value-added benefits not only for us, but also for our clients

• Our multi-location manufacturing facilities can solve or improve client’s problem of supply chain disruption

• We can assist clients who need to shift and reallocate manufacturing location to South-East Asia

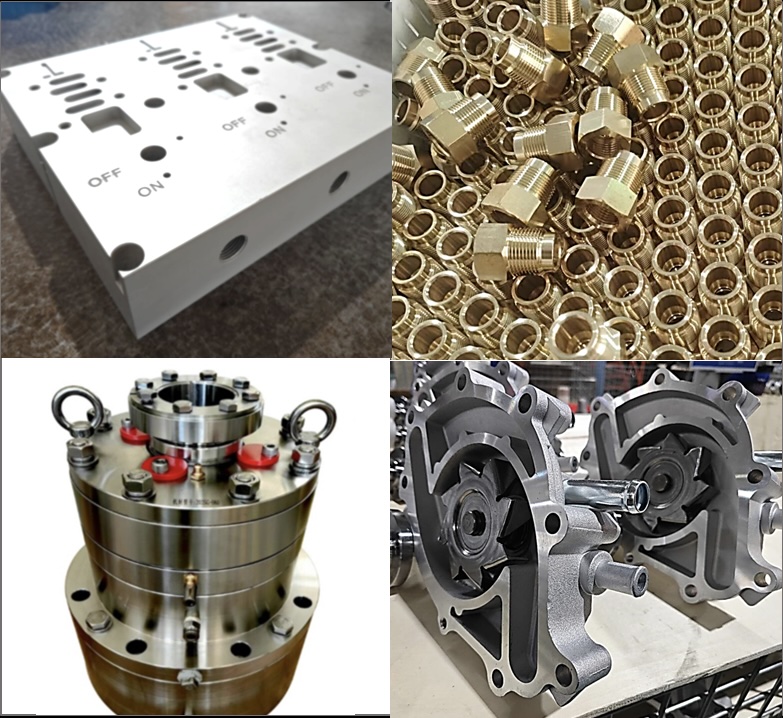

• Equipped with wide range of 3-axis, 4-axis and 5-axis CNC machine centers, turning machines, grinding machines and etc..

• Capable to handle and machine different materials, such as Aluminium, steel, stainless steel, brass, plastic, and steel/Aluminium casting

• Project Management

• Drawing and specifications review and feedback

• DFM, ECN and deviation discussion

• First article programme

• Quality plan

• We understand the quick turnaround time is a key success for our client to earn her maximum market share and revenue. We align ourselves to work fast and closely with our client’s procurement experts.

• We always give competitive prices follow with good after-services to our clients.

• We always keep training and increasing all kind of quality awarenesses to our workforces. We intensely emphasize and build the corporate culture of “Quality 1st ” to team.

• We only practice at one highest quality standard in our factories. No confusing and compromise.

• Our experienced quality personnel is able to communicate with multinational clients upon their needs.

• Quality tools and equipment are well implemented in our factory, such as smart scope, CMM and digital profile projectors.

• According to client’s forecast, raw material, semi and finished goods are stocked accordingly.

• We have warehouses in Cincinnati and Dallas (United States), Malaysia and China.

• Work with several high-efficient forwarders to manage On-Time Delivery.

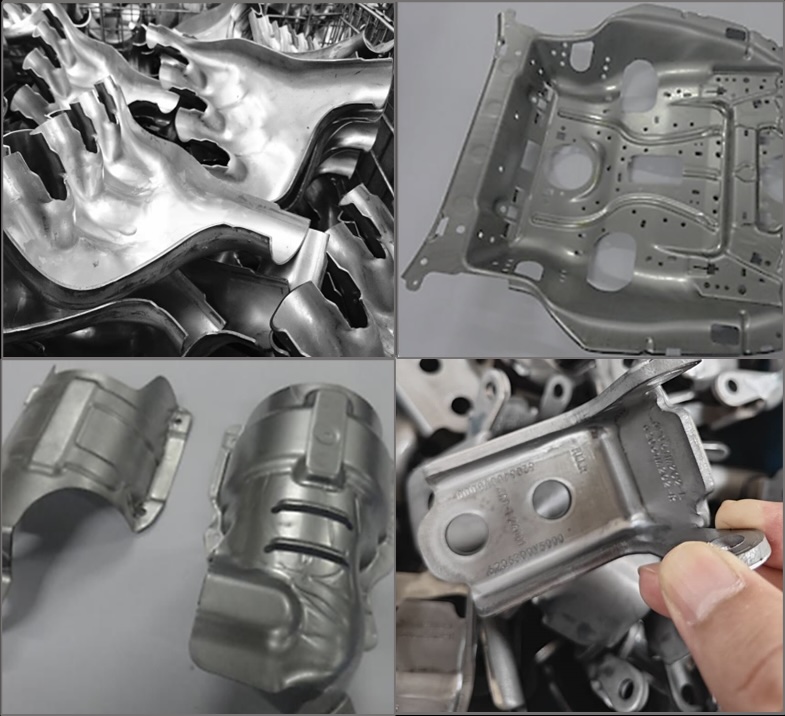

• We have in-house gravity Aluminium and Brass casting facility.

• Capable to do T5 / T6 heat treatment in-house.

• We also have supporting sources/supply chain of cast-iron and steel parts nearby our manufacturing locations, as well as we have die-casting and Aluminium extrusion partners.

• Sand blasting surface finishing for casted parts are available.

• Thanks to these casting facilities, we are ready to provide one-stop precision machining manufacturing to MNC and OEM clients.

• Total 22,000 square feet factory area

• 150 employees

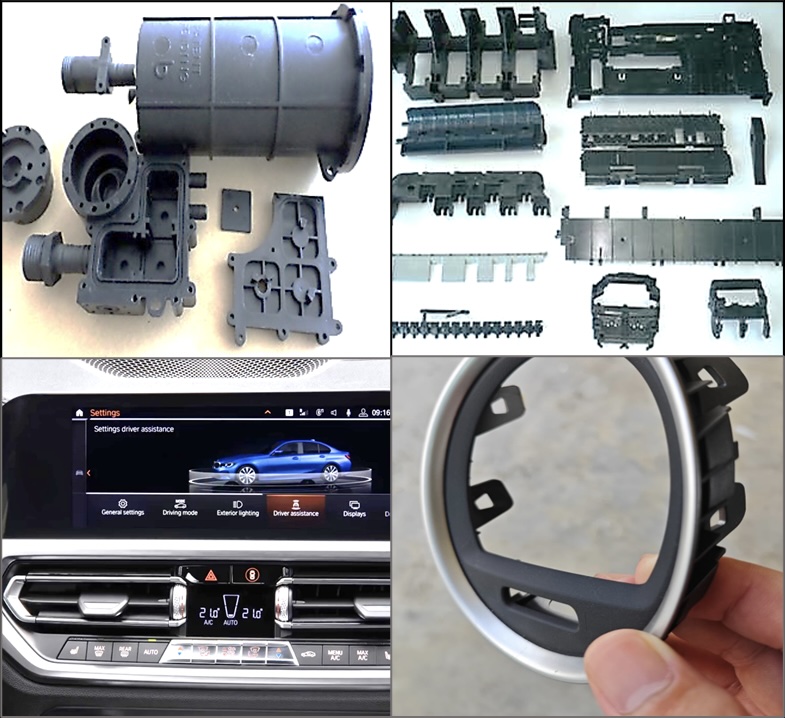

• Wide range of 40 tons – 500 tons moulding machines (56 machines)

• Dual-color injection moulding machines are available

• A plastic chrome plating line is available, especially capable for automotive parts

• We provide value-added complete product assembly and testing services (turnkey)

• Product packaging, warehouse and delivery management

• Comply with customer 3rd party’s product safety audit and certification

• Secondary processes such as silkscreen printing, paint spraying, laser engraving, chrome plating and assembly

• Quality plan and control